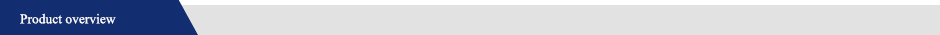

OEM Supply Two Stage Compression Air Compressor - High Pressure 280 Diesel Engine Screw Air Compressor – TDS

OEM Supply Two Stage Compression Air Compressor - High Pressure 280 Diesel Engine Screw Air Compressor – TDS Detail:

Common Uses for Compressed Air in Mines

Working in both surface-level and underground mines – many of which can stretch for miles – presents harsh and unforgiving environments. When working to extract these precious minerals and natural resources, as well as maintain safety for work crews, mining companies rely on durable, energy-efficient and safe mining equipment. Compressed air is an important source of power in nearly all mining operations. Mining companies often rely on industrial compressed air systems or portable air compressors for electric and pneumatic tools.

Because there are so many applications for compressed air in mining, most mines utilize more than one compressor on site. The most common applications include:

- Exploration drilling: During exploration drilling, an air compressor is used to drive a rotating drill bit deep into the ground.

- Smelting: This process of melting and heating is another means to extract valuable metal from ores. Compressed air is often used throughout the smelting process, which includes instrumentation, agitation and cooling.

- Agitation: Orifices in the bottom of a tank allow for air agitation. Compressed air is introduced through piping for even distribution.

- Cleaning: As a source of clean air, an air compressor is a valuable tool that can be used to clean filters and other spaces during a mining operation. Regular cleaning keeps downtime to a minimum and increases the longevity of essential mining equipment, as fewer repairs are needed.

- Material handling: Compressed air makes it easier for mining crews to handle coal dust and other very fine materials. Mixing fine particles with compressed air allows for the occurrence of fluidization. This process is helpful for conveying material.

- Refining: In the process of extracting metals from ore and other raw materials, the metal is softened by the high heat of a furnace. This process is known as refinement. During refinement, compressed air is used to oxidize any other alloys so no material goes to waste.

- Powering pneumatic tools: Wrenches, drills, saws and other critical mining equipment are often needed in deep mining environments. Air compressors provide a dependable source of power for these tools.

- Blasting: Due to the controlled use of explosives, blasting operations can be high-risk without the right equipment. Compressed air systems offer a relatively safe medium of high-velocity streams of air.

- Ventilation systems: In the deepest mine tunnels and hazardous environments, air compressor systems are used to provide clean and breathable air for miners.

Product detail pictures:

Related Product Guide:

With a positive and progressive attitude to customer's curiosity, our organization repeatedly improves our products top quality to meet the wants of consumers and further focuses on safety, reliability, environmental necessities, and innovation of OEM Supply Two Stage Compression Air Compressor - High Pressure 280 Diesel Engine Screw Air Compressor – TDS , The product will supply to all over the world, such as: Las Vegas, Italy, Hamburg, Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.

Write your message here and send it to us